- Home

- News

- The Big Cheese: Fanchi-tech FA-MD Pro True Variable Frequency Metal Detector Elevates Quality Control at CheeseCraft Solutions

The Big Cheese: Fanchi-tech FA-MD Pro True Variable Frequency Metal Detector Elevates Quality Control at CheeseCraft Solutions

The Big Cheese: Fanchi-tech FA-MD Pro True Variable Frequency Metal Detector Elevates Quality Control at CheeseCraft Solutions

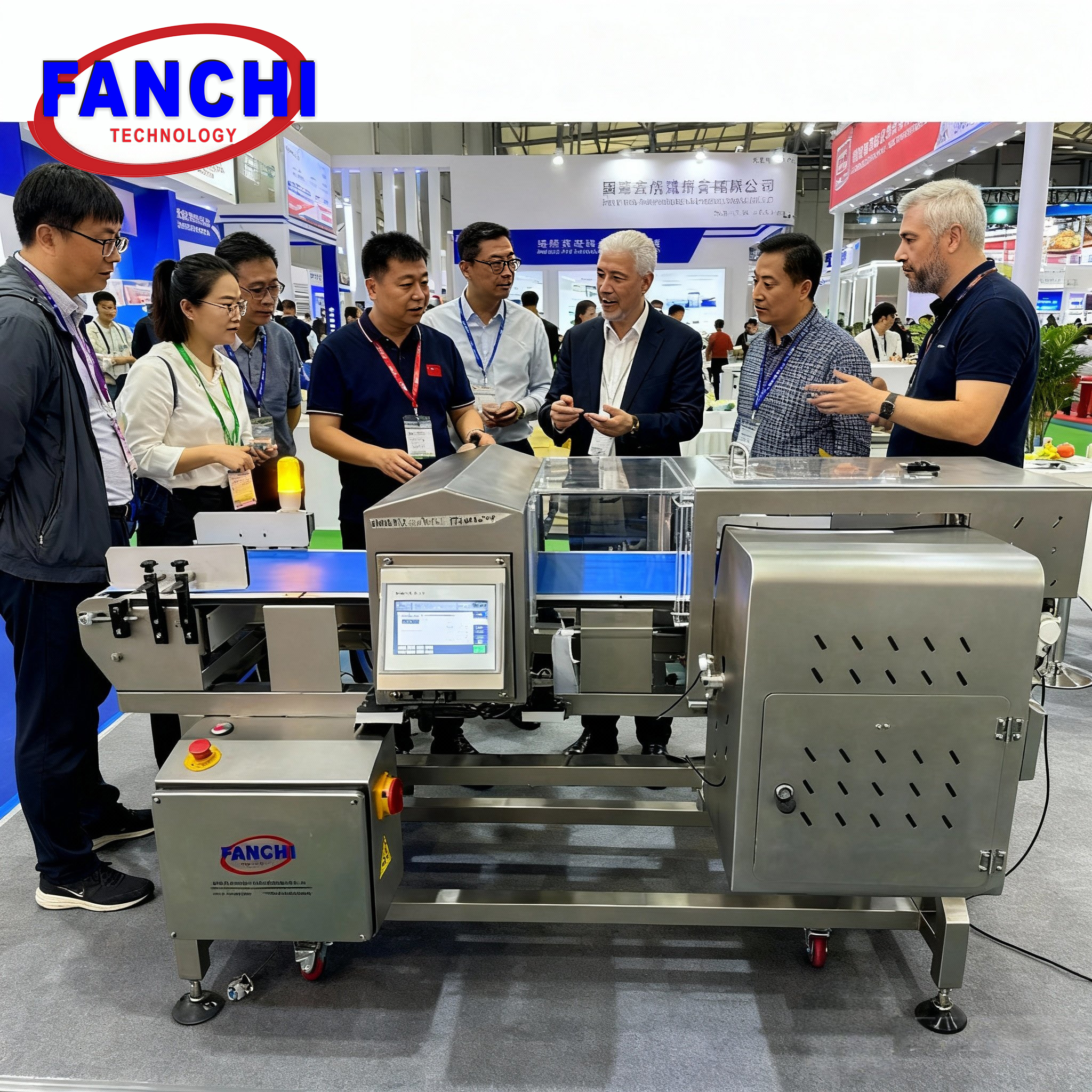

CheeseCraft Solutions—affectionately known as “The Big Cheese” in Wisconsin’s thriving dairy industry—relies on Shanghai Fanchi-tech Machinery Co., Ltd. and its FA-MD Pro Metal Detector to set new standards for quality control. Founded in 2005 by cheese enthusiast Bill Stuart and his team in Monroe, Wisconsin, the company provides slicing, cutting, and packaging services for cheese producers nationwide, converting bulk cheese into consumer-ready slices, chunks, and shreds (ranging from 8-ounce packs to 5-pound deli blocks).

Specializing in all-natural, organic, and kosher cheeses, CheeseCraft uses state-of-the-art packaging equipment—including vacuum sealers, gas flushing systems, and horizontal/vertical form-fill seals—to preserve freshness. From the start, the team prioritized flexible, high-performance inspection equipment to ensure no metal contaminants entered the final product. Today, Fanchi-tech’s FA-MD Pro—equipped with true variable frequency technology—has become the backbone of their quality assurance process.

The Challenge: Flexibility & Precision for 78+ Cheese Variations

CheeseCraft faced unique hurdles that demanded a dynamic metal detection solution:

- Extreme Product Variability: The company processes 78 different cheese types, sizes, and textures—from cheddar chunks to mozzarella shreds. Each product has distinct characteristics (moisture content, salt levels, density) that disrupt standard single-frequency metal detectors.

- Metal Contamination Risk: Cheese passes through slicers and cutters during processing, creating a risk of tiny metal fragments. Detecting these hazards was critical to meeting customer trust and industry safety requirements.

- Compromise-Free Performance: Older multi-frequency detectors forced operators to set “compromise frequencies” that worked for some products but sacrificed sensitivity for others. CheeseCraft needed a system that optimized detection for every item without trade-offs.

- HACCP Compliance & Low False Positives: Strict HACCP guidelines required reliable detection of small metal particles, while false rejects (triggered by product signature changes) threatened productivity and profitability.

- User-Friendly Operation: With a culturally diverse workforce speaking multiple languages, the detector needed an intuitive interface to minimize training time and errors.

The Solution: Fanchi-tech FA-MD Pro True Variable Frequency Metal Detector

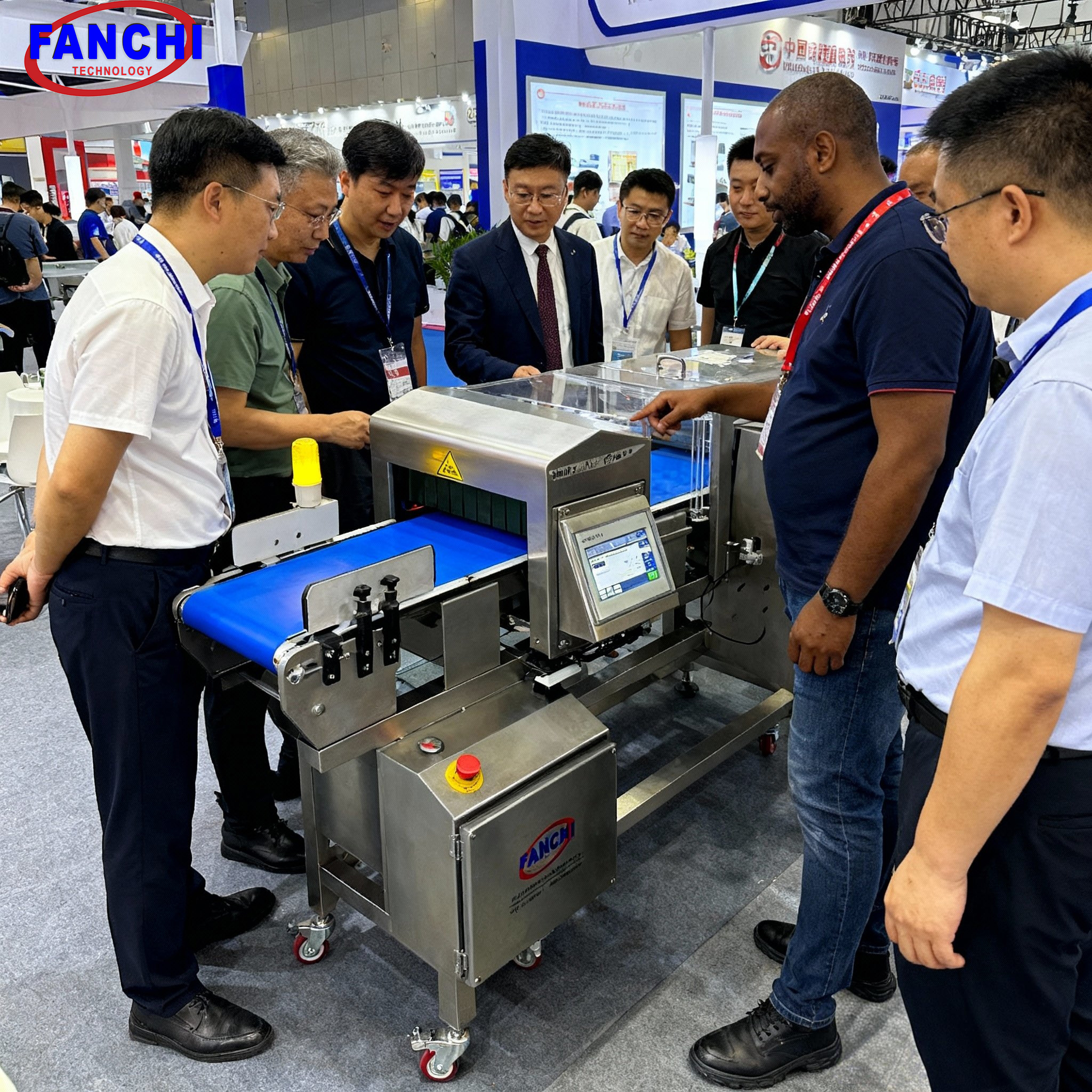

After consulting with Kerry Wang, Fanchi-tech’s North American Sales Director, CheeseCraft selected the FA-MD Pro—engineered to master variability and deliver uncompromising precision:

1. True Variable Frequency (TVF) Technology with 70 Frequencies

The FA-MD Pro’s TVF technology analyzes a broad band of 70 embedded frequencies (31–882 kHz) and automatically selects the optimal one for each product in seconds. It learns the unique “product signature” (temperature, moisture, salt content, packaging) through multiple passes, eliminating the need for manual frequency adjustments and ensuring peak sensitivity for every cheese type.

2. Seamless Multi-Product Adaptability

With the ability to store 200+ product profiles, the FA-MD Pro effortlessly switches between 8-ounce cheddar packs and 2-pound mozzarella blocks—no downtime, no compromise. This flexibility lets CheeseCraft run diverse products on the same line without sacrificing detection accuracy.

3. Ultra-High Sensitivity & Stability

The FA-MD Pro detects tiny metal fragments (down to 0.3mm ferrous, 0.4mm non-ferrous, 0.5mm stainless steel)—exceeding HACCP requirements. Its advanced coil geometry and rounded, rigid case design resist vibration, electrical interference, and thermal shock, ensuring consistent performance even in busy production environments.

4. Minimized False Rejects

By dynamically adapting to product signature changes (e.g., unfrozen cheese vs. frozen), the FA-MD Pro drastically reduces false positives. It differentiates between product effect signals and actual metal contaminants, keeping production flowing and reducing waste.

5. Intuitive Multi-Language HMI

The detector’s graphics-driven touch screen features a language-based interface (supporting English, Spanish, French, and more) and user ID access with varying security levels. This simplifies operation for a diverse team, cutting training time and ensuring consistent use.

Client Testimonial: “A Game-Changer for Flexibility & Precision”

“The FA-MD Pro has transformed our quality control,” said Bill Stuart, Plant Manager at CheeseCraft Solutions. “Before true variable frequency, we were stuck with compromise settings that missed small contaminants or triggered false rejects. Now, every product gets optimized detection—whether it’s a tiny shred or a large block.

We process 78+ cheeses, and this detector handles them all flawlessly. The touch screen is so user-friendly—our team picks it up in minutes, no matter their primary language. Installation was flawless, and we haven’t had a single issue with performance. It’s one more tool that helps us meet HACCP requirements and keep our customers happy.

More and more clients won’t do business with you without reliable metal detection. The FA-MD Pro gives us the confidence to take on any cheese conversion project—we know we’re delivering safe, pure products every time.”

Why FA-MD Pro Stands Out for Cheese Processors

For companies like CheeseCraft, the FA-MD Pro isn’t just equipment—it’s a competitive advantage:

- No Compromises: Optimized detection for every product, no trade-offs.

- Productivity: 70 frequencies, 200+ profiles, and low false rejects keep lines running.

- Compliance: Meets HACCP, BRC, and FDA standards for food safety.

- Durability: IP69K-rated search head and vibration-resistant design thrive in harsh production environments.

Elevate Your Cheese Quality Control with Fanchi-tech

Whether you process 10 or 100+ dairy products, the FA-MD Pro True Variable Frequency Metal Detector delivers the flexibility, precision, and reliability you need to protect your brand and satisfy customers.

To learn how the FA-MD Pro can tailor a solution for your operation, contact Kerry Wang at Shanghai Fanchi-tech Machinery Co., Ltd.:

- Email: fanchitech@outlook.com

- Website: www.fanchitechnology.com