- Home

- News

- Fanchi-tech’s FA-MD Metal Detectors & FA-CW Checkweighers Steal the Show at China Food Processing Expo

Fanchi-tech’s FA-MD Metal Detectors & FA-CW Checkweighers Steal the Show at China Food Processing Expo

Fanchi-tech’s FA-MD Metal Detectors & FA-CW Checkweighers Steal the Show at China Food Processing Expo

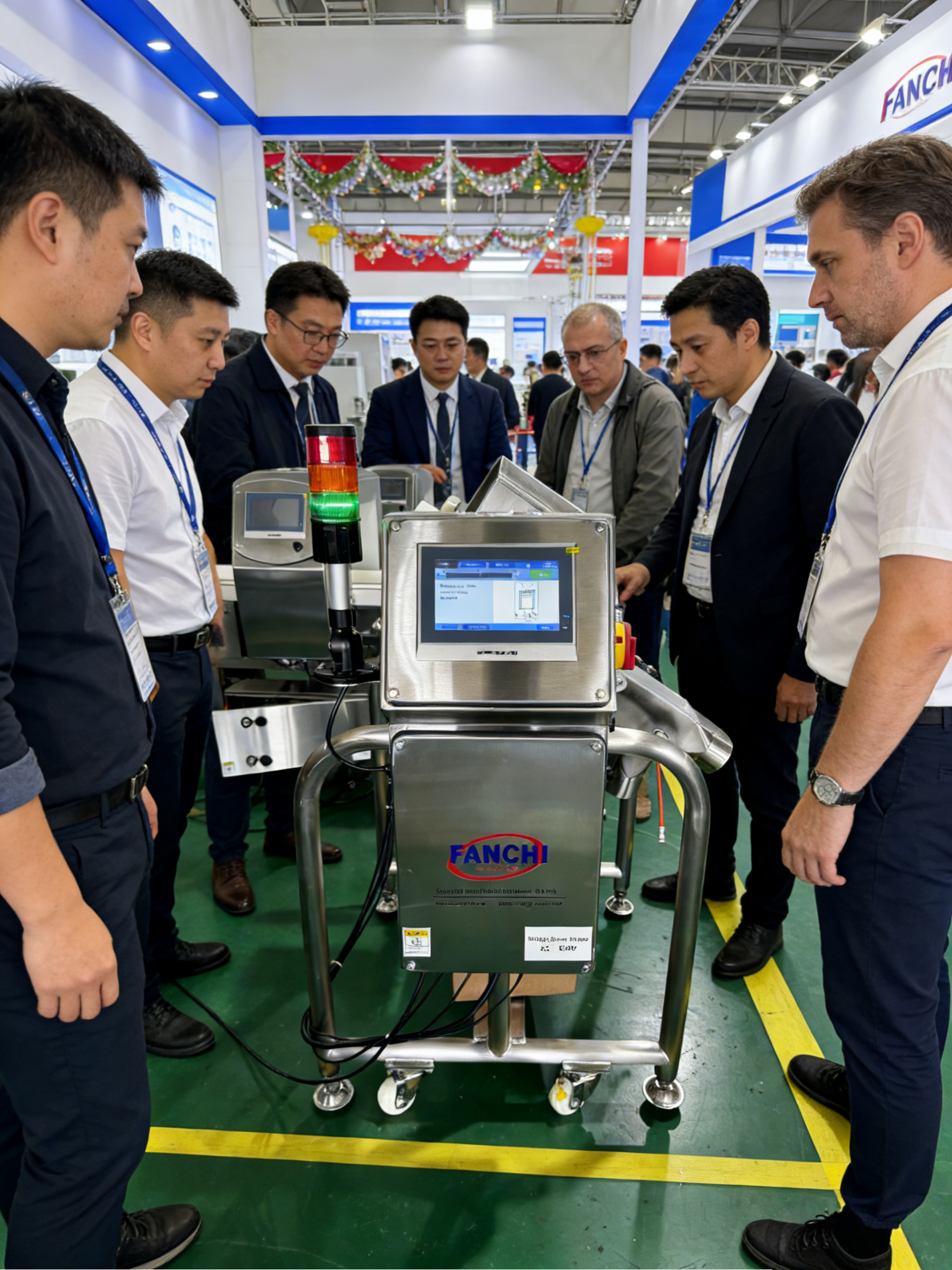

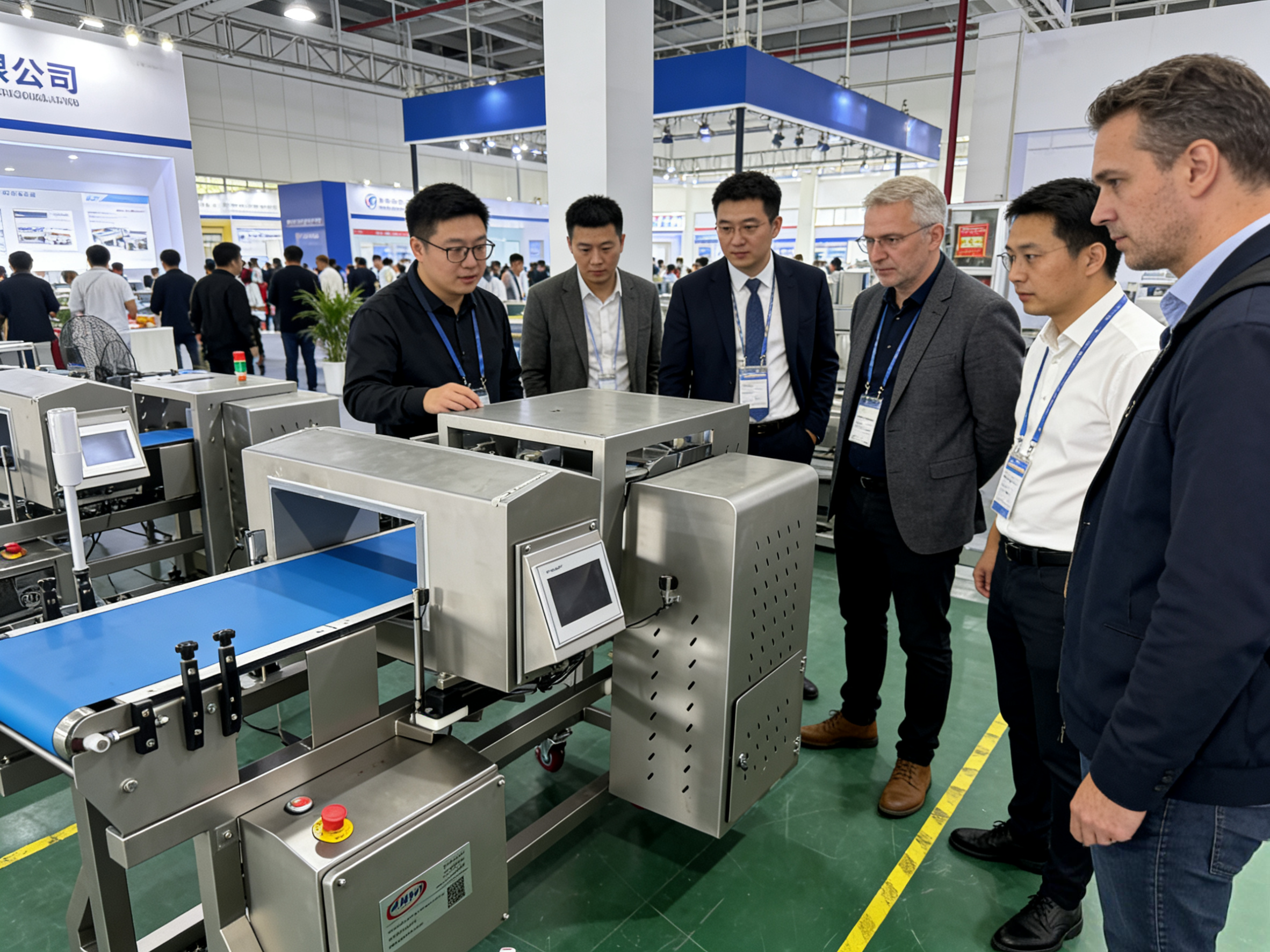

For global food manufacturers, seeing inspection equipment in action—testing its speed, precision, and ease of use—is non-negotiable before investing. This is why Fanchi-tech’s FA-MD Metal Detectors and FA-CW Checkweighers (featured at the 2025 China Food Processing Expo in Shanghai) drew crowds of 200+ international buyers, securing 12 pre-orders (including 3 from EU snack producers) during the 4-day event. The showcase highlighted how our purpose-built systems solve real-world food safety and efficiency pain points—with live demos that turned curiosity into confidence.

The Expo Showcase: Live Demos That Proved Performance

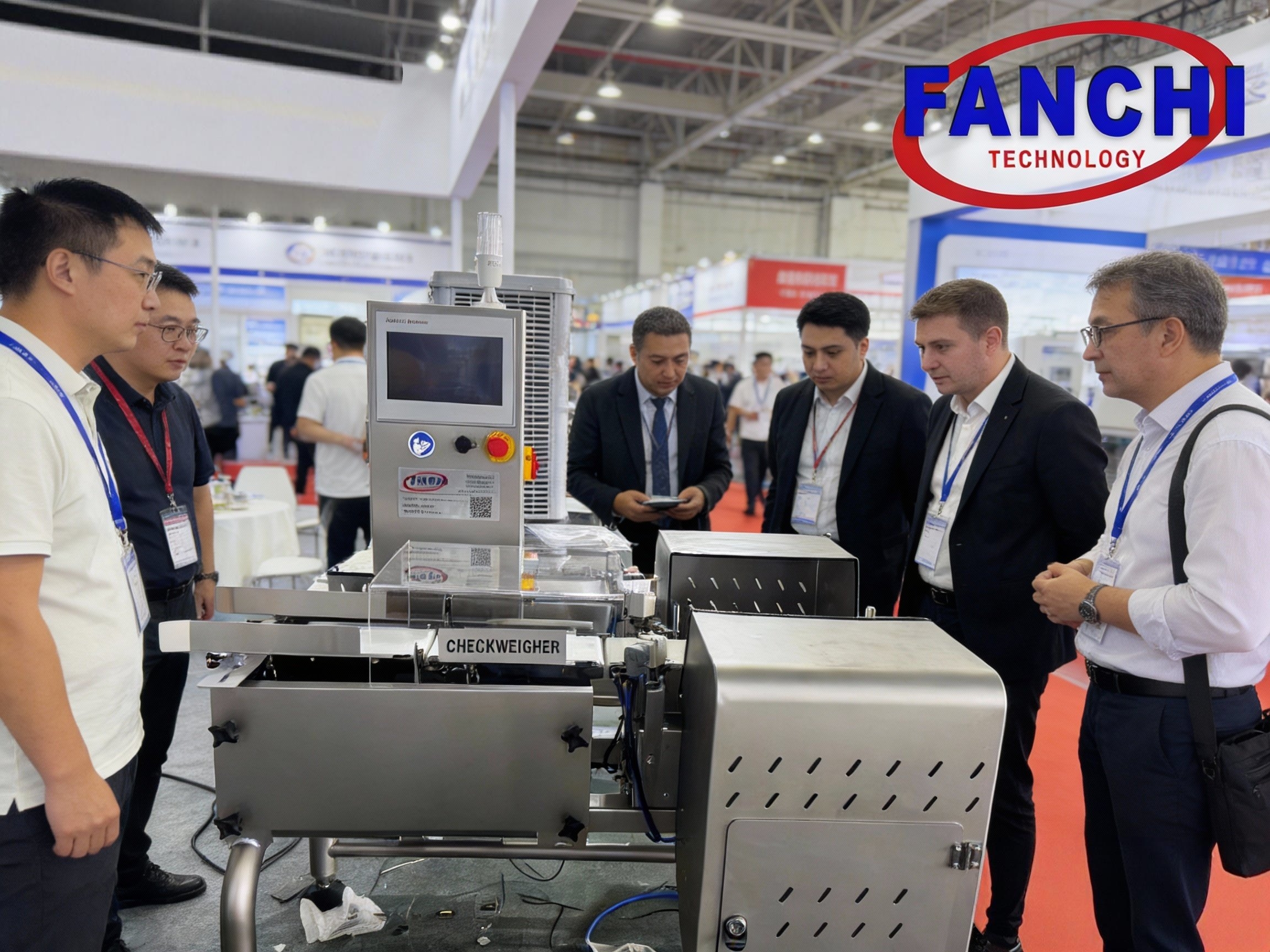

Set in Fanchi-tech’s 100m² booth (branded with our signature blue-and-red logo), the demo lineup focused on two core products, with the FA-MD Metal Detector optimized for non-seafood, non-bone-detection scenarios:

- FA-MD Metal Detectors:

We tested the unit with 15g mini almond crisp packs (the same small-format snacks from our BrightSnack case study) spiked with 0.5mm stainless-steel fragments. The FA-MD detected 100% of contaminants at 75 packs per minute—while avoiding false rejects from the high-fat product’s conductivity. A buyer from a German nut processor noted: “Our current detector misses 1 in 5 of these small fragments. This unit’s precision is exactly what we need.”

To further validate its versatility, we also ran live tests with 50g cheese cracker packs and 20g protein powder sachets, spiking samples with 0.6mm ferrous shavings and 0.8mm non-ferrous aluminum particles. The FA-MD maintained 100% detection accuracy across all test runs, with zero false rejects—a critical metric for high-volume snack and dry food producers aiming to minimize waste.

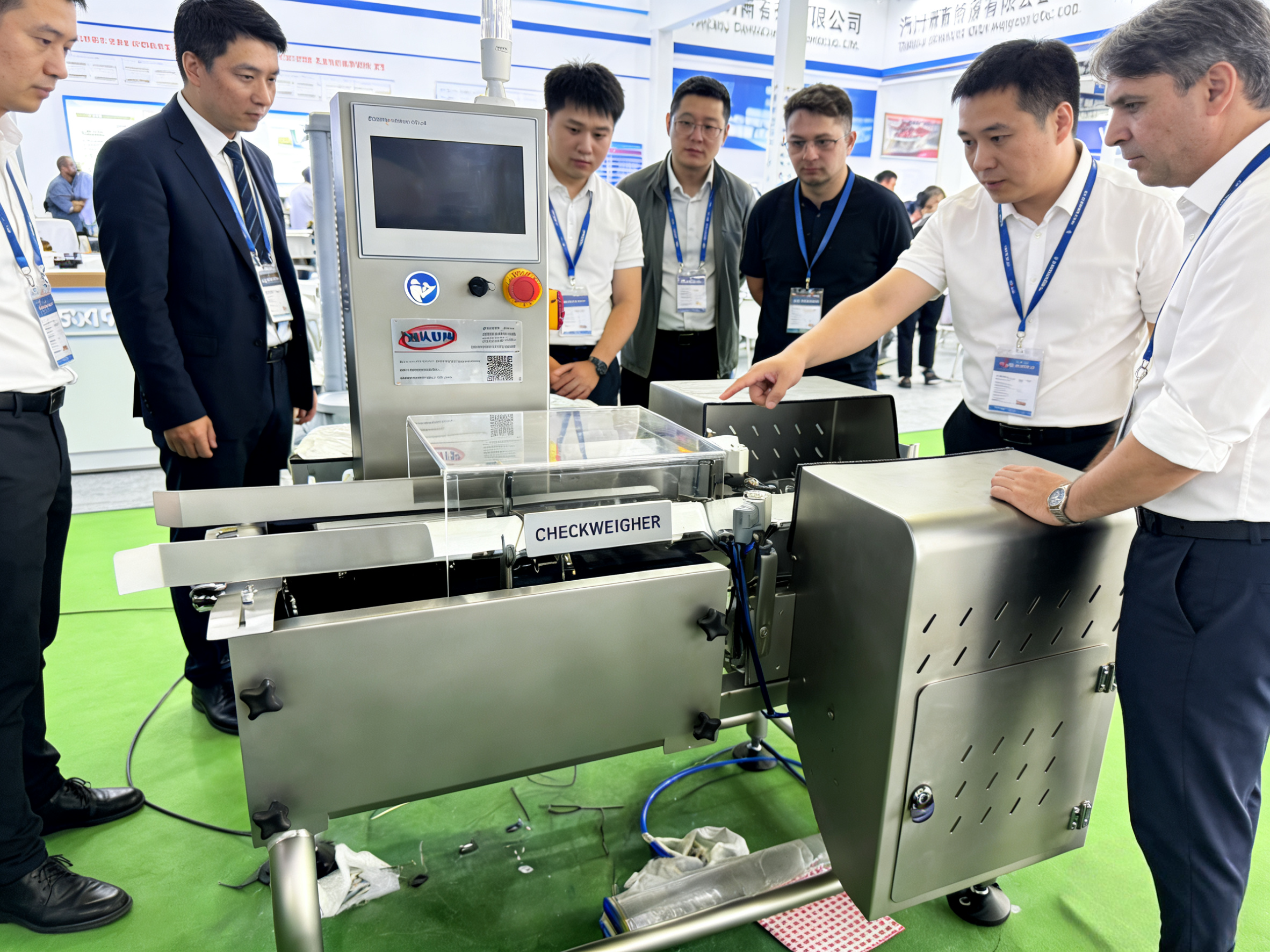

- FA-CW Checkweighers:

The demo simulated a 30g energy bar line, with the FA-CW verifying weights to ±0.6g accuracy (critical for EU weights-and-measures compliance). We also demonstrated the unit’s 30-second SKU switchover: operators called up a 5g seasoning sachet profile via the touchscreen, and the checkweigher auto-adjusted its conveyor speed and weight tolerance thresholds—impressing a French foodservice supplier who cited “10-minute changeovers” as their biggest operational pain point.

For bulk product testing, we ran 1kg cereal box samples through the FA-CW, with the system automatically rejecting packs that fell outside the ±2g tolerance range. This demo resonated with a UK breakfast cereal manufacturer, who signed a pre-order on the spot for 3 units.

The Crowd: Who Came to See Fanchi-tech?

Over 4 days, the booth hosted:

- 32 buyers from EU/US retail suppliers (including a quality manager from a UK snack conglomerate, who tested the FA-MD’s performance on chocolate-coated pretzel packs).

- 18 regional distributors (we signed 2 new partnerships for Southeast Asia and Eastern Europe, with a focus on dry food and snack production lines).

- 12 food safety auditors, who validated the FA-MD/FA-CW’s IP66 washdown rating and BRC-compliant design—critical for facilities requiring daily high-pressure cleaning.

Kerry Wang, Fanchi-tech’s Head of Global Sales, noted: “Buyers don’t just want specs—they want to see the machine work with their products. Our live tests with real snack packs, cereal boxes, and seasoning sachets made the value tangible.”

The Outcome: Pre-Orders & Global Interest

By the end of the expo:

- We secured 12 pre-orders (6 FA-MD units, 4 FA-CW units, 2 combo systems) worth $280,000, all from customers in the snack, cereal, and dry food sectors.

- 47 buyers requested on-site trials (including a Netherlands-based snack producer who booked a test for their 22-SKU mini cookie line).

- A Polish distributor signed a 3-year agreement to carry our FA-MD/FA-CW lines in Central Europe, with a focus on partnering with local bakery and snack manufacturers.

A key win came from a Spanish snack processor: “We need a metal detector that can keep up with our 80-packs-per-minute tortilla chip line and catch tiny blade fragments from our cutting equipment. Your FA-MD’s variable frequency technology checked both boxes,” they explained in their pre-order form.

Why Fanchi-tech’s Expo Demo Resonated

Unlike competitors who showed generic setups, we tailored the demos to real customer pain points in the dry food and snack sectors:

- Small-Pack Precision: Focused on the tiny contaminants that plague snack producers, from blade shavings in nut processing to metal particles in seasoning mixes.

- Speed & Efficiency: Highlighted the 30-second SKU switchovers that cut downtime for facilities with diverse product lines.

- Hygiene Compliance: Let buyers inspect the FA-MD/FA-CW’s crevice-free stainless-steel build (critical for BRC/FSMA facilities that require strict sanitation protocols).

Next Steps: Schedule Your Own Demo

If you missed the expo, contact Kerry Wang to arrange a virtual or on-site demo of the FA-MD Metal Detector or FA-CW Checkweigher. We’ll test the unit with your dry food or snack products to prove its performance for your line.

Shanghai Fanchi-tech Machinery Co., Ltd.

- Email: fanchitech@outlook.com

- Website: www.fanchitechnology.com