Fanchi-tech Checkweighers: using data to minimize product giveaways

Key words: Fanchi-tech checkweigher, product inspection, underfills, overfills, giveaway, volumetric auger fillers, powders

Making sure that final product weight is within acceptable min/max ranges is one of the critical manufacturing objectives for food, beverage, pharmaceutical and related companies. Overfills signal that the company is giving away product for which it is not being compensated; underfills mean that legal requirements are not being met which can result in recalls and regulatory action.

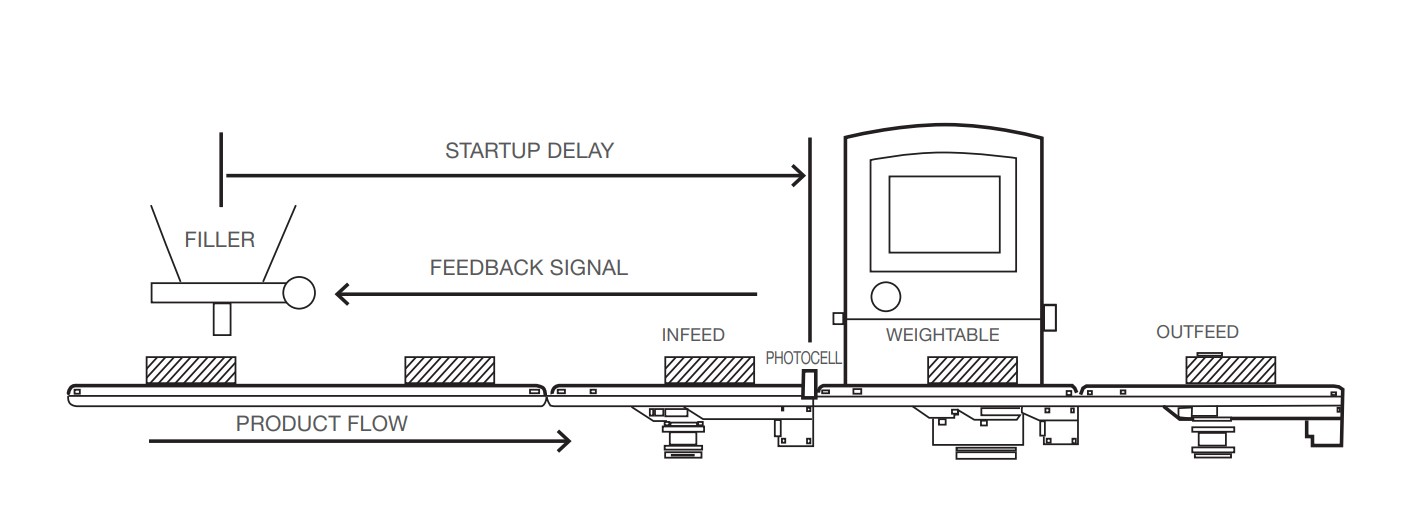

For many decades, checkweighers have been positioned on the production line after the filling/sealing operation. These units have given processors valuable information on whether or not products meet established weight criteria. However, production lines have become more sophisticated in recent years. The ability to provide critical data back to the filler in real time and/or to programmable logic controllers (PLCs) that run production lines, has made checkweighers more valuable. The objective is to be able to make filling adjustments “on the fly” so that filled package weight is always in range and unintended giveaway of high value product contents is eliminated.

This capability is particularly of benefit to volumetric auger fillers which are typically used for powdered products. Examples include:

Food: Flour, cake mix, ground coffee, gelatin Beverage: Powdered beverage mixes, concentrates Pharmaceuticals/nutraceuticals: Powdered drugs, protein powders, nutritional supplements Personal care: Baby/talcum powder, feminine hygiene, foot care Industrial/household: Printer cartridge powder, chemical concentrates

Definition: volumetric auger filler

A volumetric auger filler is a filling mechanism which measures out a product, usually powder or free-flowing solids, using an auger which is rotated for a predetermined number of revolutions in a conical hopper to discharge the required volume of product. The main benefit of these machines is their ability to control dust during the filling operation and are therefore used extensively for powders and dusty free-flowing solids. To compensate for changes in the bulk density of the product, auger fillers are frequently used in conjunction with a weighing instrument like a checkweigher. Fillers of this type are suitable for filling products at both low and medium speeds.

Volumetric auger fillers: performance attributes

The density characteristics of powdered products filled by volumetric fillers are impacted by how much is in the fill hopper. For example, if the hopper is filled close to capacity, the product on the bottom becomes more dense.(Its lightweight, small particle nature causes it to compact.) This means a lower fill volume will satisfy the printed weight requirement. As the hopper contents feed out (via the auger/timing screw) and fill the container, the remaining product is less dense, requiring a larger fill to satisfy the target weight requirements.

In this scenario, there can be significant variability within hours between over and underfills. If these are not caught at the checkweigher stage, a higher than acceptable percentage of the production run is rejected and oftentimes destroyed. Not only is production output impacted, but packaging material and labor costs also are higher.

The more efficient approach is to harness the checkweigher’s feedback capability to tell the filler in real time when adjustments need to be made.

Beyond powdered products

The checkweigher’s ability to provide feedback to the filler and/or to PLCs that run production lines is not limited to powdered products. It is also valuable for any product where the fill rate or volume can be adjusted “on the fly.”There are multiple approaches to supplying feedback information. One way is to provide weight information on a per-package basis. The production line’s PLC can take that data and trigger whatever action is necessary to keep the fill within the appropriate range.

Where this ability becomes more valuable to the food processor is in minimizing unintended giveaway. Examples include higher-value slurries and particulates in soups, sauces, pizzas and other prepared foods. In addition to auger filling (referenced in the powdered products section), piston and vibratory fillers can also benefit from feedback data.

Here’s how it works

During production, the average weight is measured over a pre-determined number of products. Target weight deviation is computed and action taken when needed via a feedback correction signal to the filler from the checkweigher. A delay is used to avoid excessive correction when the filler is in startup phase or after a product change.

The plant manager can use optional checkweigher software to feed data back to the filler. Alternatively, checkweigher data can be sent to more sophisticated production software that the processor may be using to manage manufacturing parameters.

When is an ideal time to add feedback functionality?

Plant managers and corporations are continuously watching capital expenditures and calculating payback. Adding this type of functionality to a production operation can realize payback in a reasonable amount of time, due to the cost-saving benefits outlined previously.

An ideal time to review options is when a new production line is being designed or when fillers and checkweighers are being reviewed for optimum performance. It may also be appropriate when a determination is made that there is a high percentage of expensive ingredient waste due to overfill, or if frequent underfills are putting the company in jeopardy of regulatory action or consumer complaints.

Additional considerations for optimum checkweighing

It’s also important not to overlook some basic guidelines for optimum checkweigher performance. These include:

• Locate the checkweigher in close proximity to the filler

• Keep your checkweigher in good repair

• Make sure that the feedback signal is properly integrated with the filler

• Maintain proper presentation (spacing, pitch) of product to the checkweigher

Learn more

The financial benefit for each company can vary greatly depending on the amount and cost of product giveaway that can be significantly minimized with valuable real-time data.

If you would like to get more information on how we can assist you with your product inspection requirements, please contact us at fanchitech@outlook.com.